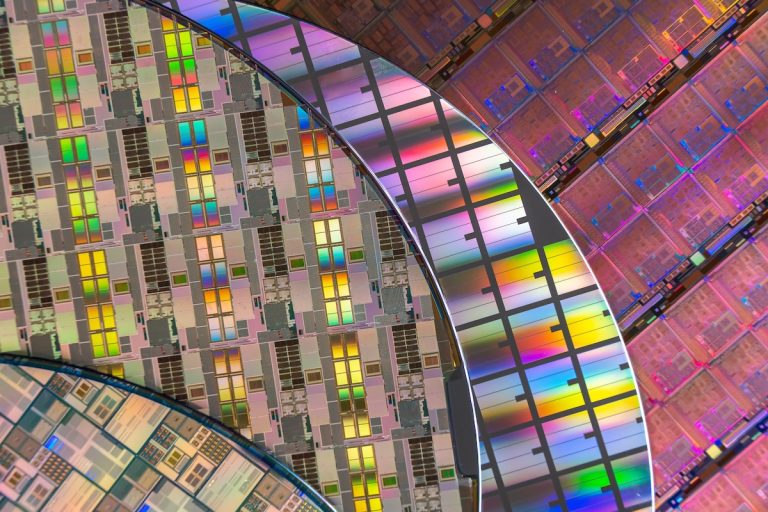

Artificial Intelligence and Machine Learning (AI/ML) has immense power to transform semiconductor design and manufacturing for a wide and varied variety of applications. Just consider the volume of data generated each year by design and manufacturing. With increasingly complex products, machines, processes and supply chains, the overall amount of data associated with semiconductor manufacturing is exploding.

Big opportunities arise at the intersection of AI data and manufacturing execution systems (MES), defect detection and sensor-based diagnostics. Integrating physics-based models with a digital twin of factories, equipment and end-to-end supply processes or predicting risks at different failure points are also opportunities for new physics-based solutions. ‘AI.

Until now, the potential of AI/ML and data-driven innovation has been limited by the challenges of secure and scalable data sharing in verification, validation and uncertainty quantification capabilities. (VVUQ) offline or in real time, hindering the ability to adapt to changing conditions. with built-in AI intelligence.

The smart manufacturing of the semiconductor industry in 2024 will be different, as sophisticated and highly advanced AI tools, including GenAI, will be available to analyze large data sets and provide new insights.

While semiconductor manufacturing and testing generates enormous amounts of data, traditional analysis methods focus on a small subset of that data. Adequate data infrastructure was not always available to handle the volume of data created and analysis models were developed based on a small number of parameters. This meant insufficient parameter coverage, and the modeling and predictive insights were not able to account for all available data. An AI-based approach will be able to take into account all available data to determine which parameters are most important to obtain meaningful insights.

Another limitation of traditional analysis methods is the focus on a single area for design, manufacturing or testing. AI’s ability to handle much larger data sets provides the ability to examine a larger data space and answer questions across multiple domains.

What sets AI apart is its ability to create a unique and superior model. Although many AI efforts focus on finding “better models,” they remain in the pilot stage and are never deployed at scale. A few important elements are needed for AI to make an impact in the semiconductor context at scale. The first is a data infrastructure capable of bringing together large amounts of data at high speed from design, manufacturing and testing. The second is an extended semantic model for gathering and aligning data from different process areas. The ability to develop or leverage the best models, including models developed by third-party teams and organizations, comes third.

Finally, to be effective, AI must not only support the development of models, but also enable those models to be deployed and monitored where they will be used for decision-making and process control, often in real time. For example, unless AI models for testing can be deployed where testing is performed, they will not help improve device quality in the globally distributed supply chain of 3D hybrid systems complex. This comprehensive approach to AI and infrastructure combining data, semantics, model development and deployment, and lifecycle management is known as ModelsOps.

Massive investments are being made to create new semiconductor facilities. These new factories will often be smaller than the largest and most productive existing factories. AI will be key to accelerating learning and process integration to make advanced manufacturing plants as productive as established, larger plants.

As the semiconductor industry faces a talent challenge as the current workforce ages, the need for new talent outpaces graduation rates. AI will be key to “democratizing” analytical decision-making and enabling more employees to use the best AI models to make optimal design and manufacturing decisions without analytics experts. data.

PDF Solutions and other industry experts will discuss real-world applications of AI in the semiconductor industry at the AI Executive Conference on Thursday, December 12 in San Francisco. Registration is open.

John Kibarian

John Kibarian is President, CEO and Co-Founder of PDF Solutions. He has served as president since 1991 and CEO since 2000. Kibarian holds a Bachelor of Science in electrical engineering, a Master of Science, and a PhD in computer engineering from Carnegie Mellon University.