- The first cassette-based solution to the market for two-phase immersion cooling significantly reduces the time and costs associated with installing and upgrading hyperscale data centers.

- Plug-and-play deployment easily connects dip tank optical transceivers to cabling infrastructure via fully scalable sealed modules

- Scalable capabilities include the flexibility to change connector types and change circuit configurations without impacting mechanical interfaces or tank design.

LISLE, IL – Media OutReach Newswire – September 26, 2024 – Molexglobal electronics leader and connectivity innovator, today introduced a thermal management solution that reduces the time and cost of deploying and upgrading high-performance data centers to meet relentless demand generative AI and machine learning workflows. Molex VaporConnect™ Optical Feedthrough Modules for two-stage immersion cooling, addresses continued increases in data center speed and capacity by leveraging a unique cassette-based design that bolts directly to immersion tanks and allows for swap optical transceivers and network cabling infrastructure without changing mechanical interfaces or impacting the dip tank. architecture. Reference designs for the new modules will be commercially available in the first quarter of 2025.

“Molex is continually adopting innovative optical solutions to facilitate data center deployments and upgrades while mitigating critical thermal management challenges,” said Trevor Smith, general manager of optical connectivity at Molex. “VaporConnect offers customers the flexibility to upgrade connectivity and evolve cooling system designs to keep pace with data center growth by simply deploying a different module, which will accelerate upgrades while reducing overall energy, cooling and technology costs. »

Streamlining two-phase immersion cooling

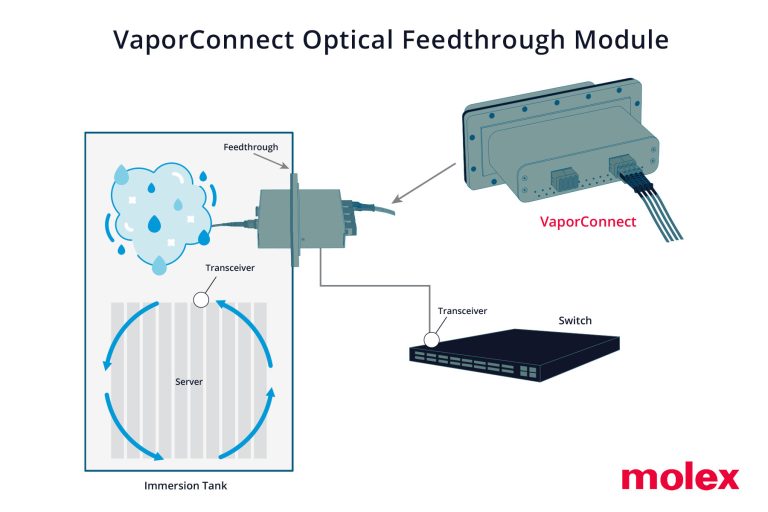

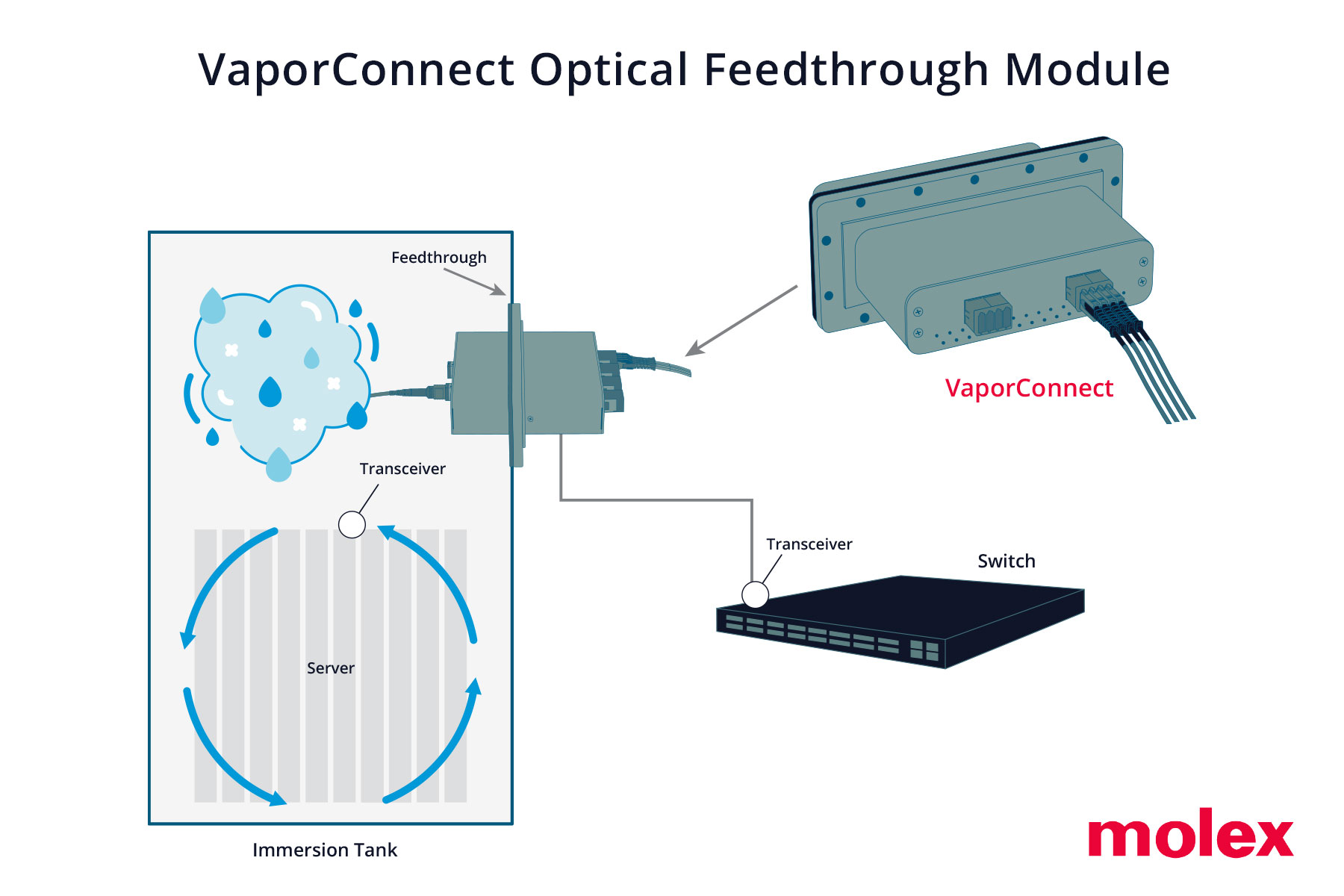

Molex VaporConnect optical feed-through modules simplify connections between optical transceivers contained within immersion tanks and the cabling infrastructure that exists outside the tank using fully scalable sealed modules. With VaporConnect, sealing and wiring is done inside the module, giving customers the ability to upgrade connectors without affecting the design or architecture of the dip tank. Additionally, customers have the ability to reuse standard cabling infrastructure across multiple product generations, further reducing deployment time, cost and complexity.

A full range of Molex and industry standard optical connector form factors are available for single-mode and multi-mode fiber solutions. They also have mixing functionality to facilitate system upgrades to newer or denser connectors. Customizable module footprints are available to meet specific space and application requirements. Additionally, Molex VaporConnect optical feed-through modules are designed to minimize external patching and patching requirements by leveraging Molex FlexPlane™ optical circuit technology. As a result, complex optical mixes and high-density fiber routing are seamlessly integrated into the module for simpler plug-and-play installation and operation.

Reliable, versatile and scalable optical interconnects

A gasket is provided with each VaporConnect module, which is thoroughly tested using industry-standard helium leak tests to ensure a reliable seal with the tank wall. This also ensures a seamless transition from server line cards inside the tank to the external cabling infrastructure. Testing is underway to verify compliance with industry standard GR-1435-CORE.

VaporConnect modules are designed to meet customer specifications, with the number of fiber channels depending on the number and type of connectors used. Up to 576 fibers can be integrated into a single module. A range of form factor options are available, including MPO, LC and very small form factor (VSFF) options, such as MMC, MDC, SN and SN-MT. This ensures compliance with existing infrastructure and streamlines system upgrades. As part of Molex’s continued investment in this area, an EBO connector option is currently under development, with availability planned for the first half of 2025.

Molex’s commitment to optical networking innovations on display at ECOC 2024

As the largest manufacturer of optical feed-through modules for two-phase immersion cooling, Molex has shipped more than 350,000 optical channels to date. To this year CEC’24Molex will reinforce its commitment to innovations in optical network infrastructure with on-site product demonstrations, including the new VaporConnect optical feedthrough modules. The company’s wide range of optical connectivity products, optoelectronic solutions and wavelength management systems will also be showcased at booth C75. As a participating member of OIF, Molex is participating in an interoperability demonstration, taking place at booth B83, to highlight optical networking innovations and solutions for data centers, AI/ML technologies and disaggregated systems.

Hashtag: #Molex

About Molex

Molex is a global electronics leader committed to making the world a better, more connected place.. With a presence in more than 40 countries, Molex enables transformative technology innovation in the automotive, data center, industrial automation, healthcare, 5G, cloud and consumer device industries. Through trusted customer and industry relationships, unmatched engineering expertise, and product quality and reliability, Molex realizes the infinite potential of Create bonds for life. For more information, visit ![]() www.molex.com.

www.molex.com.